The Smart Way to Produce DEF: On-Site Production with | EraBlue Tech

- October 3, 2025

In today’s fast-paced world, efficiency, cost-effectiveness, and reliability are paramount for any business operating diesel fleets. One critical component often overlooked in the grand scheme of operational costs and logistics is Diesel Exhaust Fluid (DEF). While essential for modern diesel engines, sourcing DEF can present significant challenges.

But what if you could take control? What if you could produce high-quality DEF on-site, precisely when and where you need it? This isn’t a pipe dream; it’s a reality with advanced DEF Making Machines.

What Exactly is DEF, and Why is it So Important?

For those new to the specifics, Diesel Exhaust Fluid (DEF) is a non-toxic solution of urea and de-ionized water. It’s crucial for diesel vehicles equipped with Selective Catalytic Reduction (SCR) technology. When injected into the exhaust stream, DEF converts harmful nitrogen oxides (NOx) into harmless nitrogen and water vapor, significantly reducing emissions and helping fleets meet stringent environmental regulations. Without DEF, your modern diesel engines won’t just fail to meet emissions standards – they may even enter “limp mode” or refuse to start.

The Hidden Costs and Headaches of Sourcing Traditional DEF

For years, businesses have relied on purchasing pre-made DEF from external suppliers. While seemingly convenient, this approach comes with its own set of challenges:

- Fluctuating Costs: The price of DEF can be volatile, impacting your budget predictability.

- Supply Chain Vulnerabilities: Delays, shortages, and logistical issues can leave your fleet stranded, impacting uptime.

- Quality Control Concerns: Not all DEF is created equal. Substandard DEF can damage your SCR system, leading to costly repairs.

- Storage & Handling: Managing bulk deliveries, storage tanks, and smaller containers requires space and careful handling.

- Environmental Footprint: The transportation of DEF and the disposal of plastic containers contribute to your carbon footprint.

Introducing the EraBlue Technology DEF Making Machine: The Game Changer

Imagine a solution that addresses all these pain points while empowering your business with greater control and independence. Our DEF Making Machine offers exactly that – a smart, efficient, and reliable way to produce ISO 22241-compliant DEF right at your facility.

How It Works: Simplicity in Every Drop

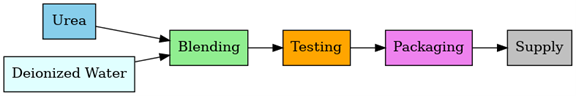

Our machine demystifies the DEF production process, making it straightforward and automated.

Pure Water Input: The process begins with clean, readily available water, which is then de-ionized to meet strict purity standards.

Technical Grade Urea Supply: We introduce a precisely measured amount of automotive-grade urea, the essential raw material.

Precision Blending & Filtration: Our system intelligently mixes the urea and de-ionized water, ensuring the exact 32.5% concentration required for optimal performance. Multiple stages of filtration guarantee unparalleled purity.

Integrated Quality Assurance: Built-in sensors and testing protocols continuously monitor the DEF, ensuring every batch meets the rigorous ISO 22241 international standards for quality and consistency.

On-Demand Dispensing: Once produced, the high-purity DEF is ready for immediate use, either stored in your facility’s tanks or dispensed directly into your vehicles.

Beyond the Basics: Unpacking the Key Benefits (KPIs)

Investing in an on-site DEF production solution isn’t just about making fluid; it’s about making smart business decisions.

- Significant Cost Savings: By producing your own DEF, you eliminate supplier markups, transportation costs, and various handling fees. Many businesses see their cost per gallon drop dramatically, leading to substantial savings over time and a rapid return on investment.

- Unparalleled Operational Efficiency & Supply Security: Say goodbye to waiting for deliveries or stressing over supply chain disruptions. With an on-site DEF Making Machine, you have an uninterrupted, 24/7 supply, ensuring your fleet never experiences downtime due to DEF shortages. This translates to maximized uptime and streamlined logistics.

- Guaranteed Quality Control: Poor quality DEF can lead to costly SCR system repairs and voided warranties. Our machines ensure every drop of DEF produced meets or exceeds the critical ISO 22241 standard, safeguarding your engines and your peace of mind.

- Scalability for Any Fleet Size: Whether you operate a small local fleet or a large national operation, our machines are designed to meet varying production demands, growing with your business.

!["Benefits of a DEF Making Machine: cost savings, operational efficiency, quality control"]](https://erabluetech.com/wp-content/uploads/2025/10/WhatsApp-Image-2025-07-14-at-13.18.21_aa080050-1024x459.jpg)

Driving Greener: The Environmental Edge

Beyond the financial and operational benefits, choosing on-site DEF production demonstrates a clear commitment to environmental stewardship.

- Reduced Carbon Footprint: By eliminating the need for frequent DEF deliveries, you significantly reduce the fuel consumption and emissions associated with transportation.

- Less Plastic Waste: Say goodbye to countless plastic DEF containers, barrels, and jugs that contribute to landfill waste. Your machine helps minimize packaging waste, supporting a more sustainable operational model.

- Consistent Emissions Reduction: Ensuring a constant supply of high-quality DEF means your diesel engines can consistently perform at their peak emissions-reducing efficiency, contributing to cleaner air.

Who Benefits Most from an On-Site DEF Making Machine?

While virtually any organization consuming a significant amount of DEF can benefit, industries that see the most dramatic positive impact include:

- Trucking & Logistics Companies: Keeping large fleets moving efficiently is crucial.

- Agricultural Operations: Remote locations often struggle with DEF supply and high delivery costs.

- Construction & Mining: Heavy machinery relies heavily on DEF, often in challenging environments.

- Municipalities & Public Works: Ensuring essential services continue uninterrupted.

- Bus & Transit Fleets: Consistent, reliable DEF supply for urban and regional transport.

Take Control of Your DEF Future Today

The decision to transition to on-site DEF production is a strategic move that pays dividends in cost savings, operational stability, and environmental responsibility. Stop reacting to market fluctuations and supply chain woes. Start proactively managing your DEF needs with a solution that puts you in control.

Ready to revolutionize your DEF supply?

EraBlue Technology is here to help you explore the perfect DEF Making Machine solution for your specific requirements.

Contact us today for a personalized consultation and a detailed ROI analysis!

Outsourcing vs In-House DEF: Which Wins?

Previous BlogWhy 2025 is the Last Chance to Enter the DEF Manufacturing Business

Next BlogCopyright © 2023 ERABLUE TECHNOLOGY PVT. LTD. GUJARAT, INDIA. All rights reserved.

Disclaimer: AdBlue® is a registered trademark of the Verband der Automobilindustrie e. (VDA)