Project Description

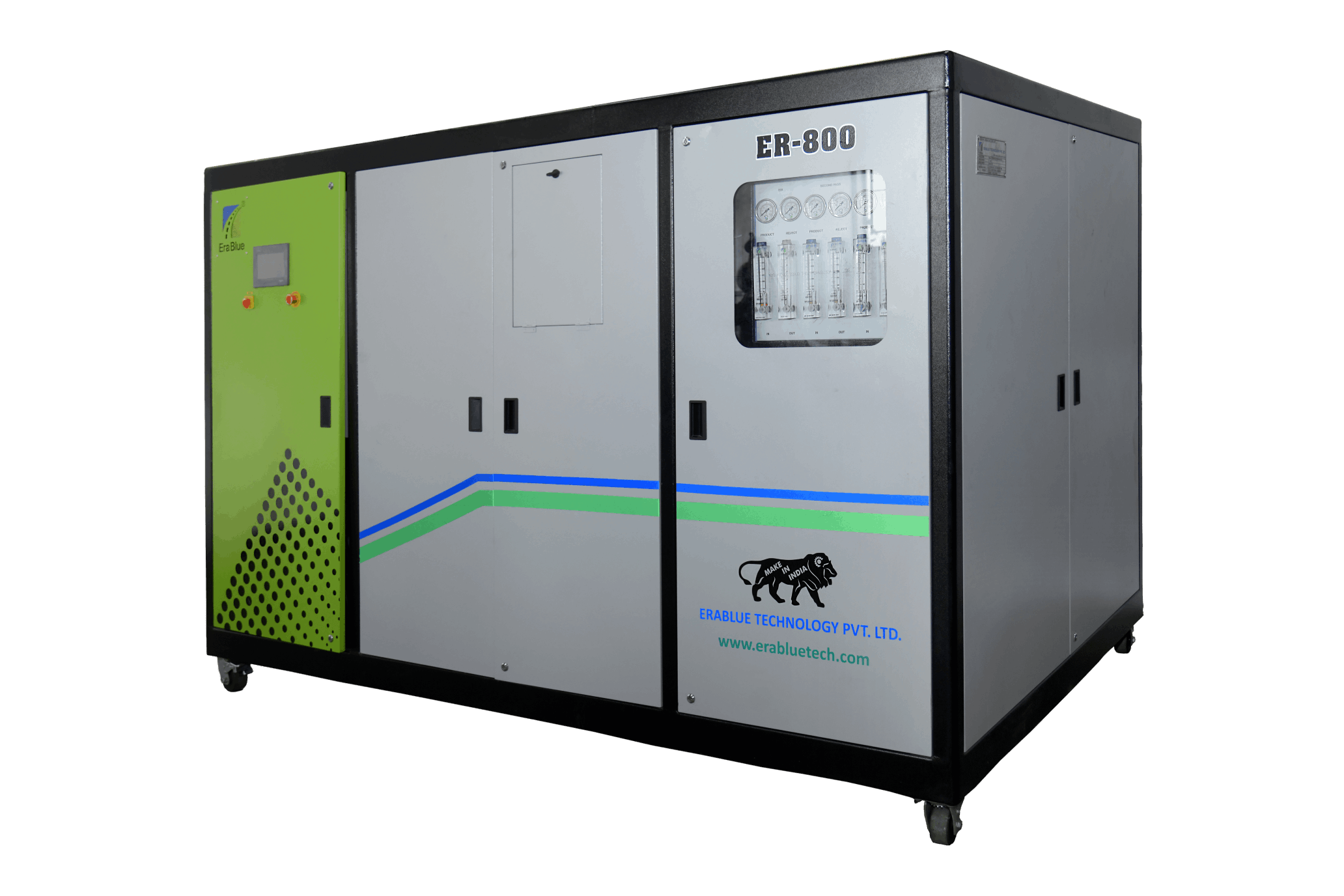

| Element | Specification |

|---|---|

| Machine Model | ER-800 |

| Production Capacity | 8000 L in 10 hours |

| Machine Built Quality | Heavy Structure, AdBlue Quality Sensor, Fully Automatic Operation by Industrial PLC with HMI, Filter Replace Notification |

| Power Requirements | 22 KW / 3 Phase |

| Weight | 750 Kg |

| Dimension | 3000 x 1775 x 1860 MM |

| Installation | Free in India with Trial & Training |

| Warranty and Support | 01 Year Limited |

| Consumable | On Demand |

| Operate | Easy To Operate With Plug & Play System In Low Maintenance |

| Grade Standard | ISO |

| Country of Origin | Made in India |

| Automation Grade | Automatic |

Looking to start your own DEF Making Business? The ER-800 DEF Plant is the perfect entry-level model, delivering 8000

liters of high-quality AdBlue® (Diesel Exhaust Fluid) in just 10 hours.

This fully automated, plug-and-play system is designed for small-scale businesses, fleet owners, and workshops aiming for cost-effective DEF production.

➤ Affordable Startup Solution – Low power consumption & easy operation.

➤ Free Installation & Training – Get up and running with expert support.

➤ 1-Year Warranty – Ensuring peace of mind and smooth operations.

Get Your Answer Here

What is DEF?

Why is DEF important for diesel engines?

DEF is essential for reducing emissions and ensuring compliance with environmental

regulations like EPA and Euro 6 standards. It helps diesel engines run cleaner, improves

fuel efficiency, and extends the lifespan of exhaust system components.

How does DEF reduce emissions?

DEF is injected into the exhaust stream of diesel engines, where it reacts with NOx

gases in the SCR catalyst. This reaction converts harmful emissions into harmless

nitrogen and water vapor, significantly reducing air pollution.

What are the key components of DEF?

DEF is made up of two primary components:

- High-purity urea (32.5%) – A synthetic compound used in

fertilizers and industrial processes. - Deionized water (67.5%) – Ultra-purified water free from

minerals and contaminants.

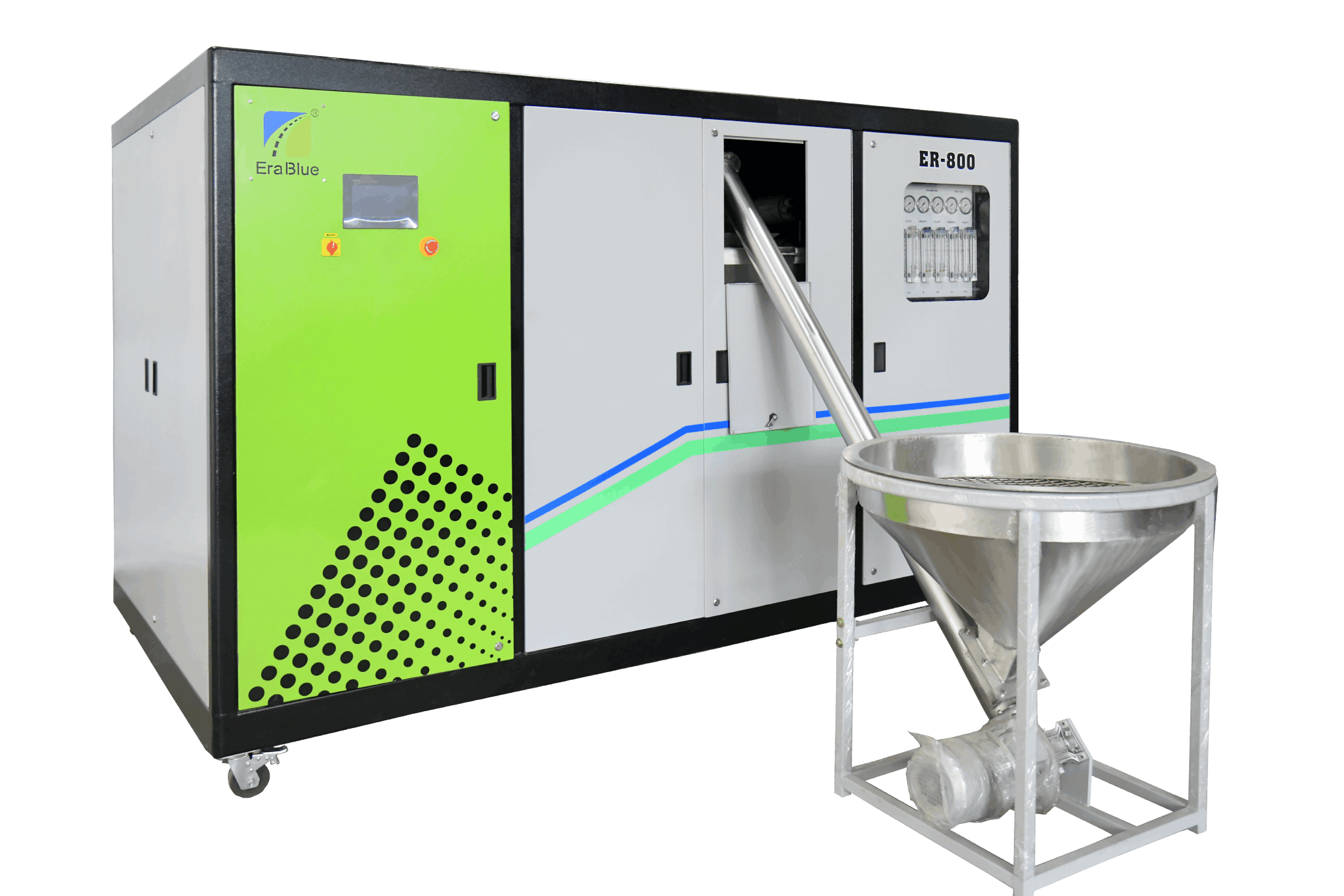

AdBlue ® Manufacturing process

AdBlue® / DEF production process involves dissolving solid urea (also known as urea

prills) in de-ionized water using mixing/blending units. While DEF

production involves a simple blending process, it is critical to

take adequate measures to ensure quality control and compliance to ISO 22241 standards.