In today’s emission-regulated market, investing in a DEF Making Machine is not just a choice—it’s a necessity. For businesses aiming to capitalize on the growing demand for Diesel Exhaust Fluid, EraBlue offers an advanced, automated solution that simplifies production and boosts profits.

Whether you are a newcomer planning to start your own DEF production business or an established enterprise looking to scale up, this blog dives deep into why our DEF Making Machine stands out, how it outperforms competitors, and real stories of businesses that have grown using it.

What Is a DEF Making Machine?

Diesel Exhaust Fluid (DEF) is essential for reducing emissions from diesel engines, especially in commercial transportation, mining, and heavy equipment sectors. A DEF Making Machine automates the process of blending urea with deionized water to produce high-purity DEF that meets ISO 22241 standards.

Key Features of EraBlue’s DEF Making Machine

EraBlue’s engineering brilliance is backed by 7+ years of industrial water treatment expertise, resulting in a machine that’s reliable, scalable, and fully optimized.

1) 24/7 Uninterrupted Operation:

Our machines are engineered for continuous production, with a smart control system that ensures zero downtime—ideal for high-demand businesses.

2) Multiple Production Capacities

Choose from production capacities of:

This flexibility allows startups and large-scale manufacturers to find the perfect fit.

3) Fully Automated Process

- Touchscreen PLC Panel

- Auto-Dosing & Auto-Mixing

- Real-time Monitoring

The system eliminates manual errors and ensures consistent product quality.

4) ISO 22241 Compliance

Our machines are designed to strictly follow DEF quality guidelines, ensuring compatibility with all SCR-equipped vehicles globally.

5) Plug-and-Play Setup

Comes pre-installed and requires minimal site preparation, cutting down setup time and operational delays.

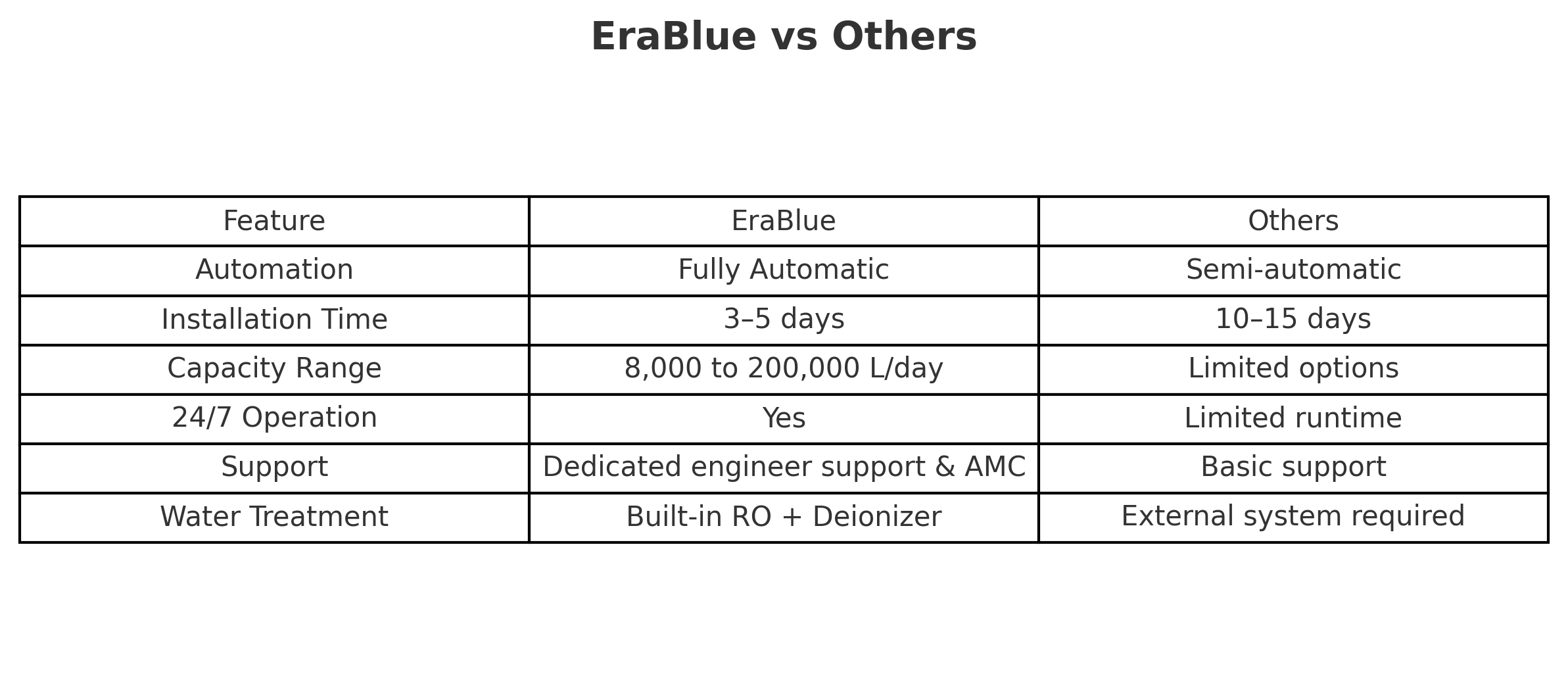

Bottom Line: EraBlue’s machines offer higher capacity, smarter control, quicker deployment, and better long-term reliability.

Real Business Impact: Case Studies

Case Study 1: From Zero to 100K Liters a Day

Client: Logistics startup in Gujarat

Problem: Needed quick setup and immediate production to meet a government contract

Solution: Installed a 100,000-liter machine within 5 days

Result: Generated ROI in just 3 months and expanded to a second unit in under a year

Case Study 2: Mining Company Saves Millions

Client: Mining operator in Rajasthan

Problem: Importing DEF was expensive and logistically complex

Solution: In-house DEF production with 200,000-liter unit

Result: Cut procurement cost by 45%, gained control over quality, and reduced downtime

Case Study 3: Young Entrepreneur Turns Vision into Business

Client: First-time business owner

Problem: Wanted a stable, long-term business

Solution: Started with an 8,000-liter machine

Result: Now supplies DEF to local transporters and highway fuel stations, expanding into multiple cities

How Our DEF Making Machine Helps You Overcome Industry Challenges

1) High Cost of Outsourced DEF

— Reduce per-liter cost dramatically by in-house production

2) Uncertain Quality from Third Parties

— Maintain consistency and control with every batch

3) Regulatory Compliance Pressure

— Meet ISO standards automatically, protect your business

4) Limited Scalability

— Upgrade capacity as you grow without changing the core system

Who Should Consider This Machine?

- Entrepreneurs seeking a profitable and sustainable business

- Transport companies wanting to reduce DEF cost

- Fuel station chains looking to offer additional value

- Mining & heavy industry operators aiming for in-house production

- Agro-logistics & vehicle fleet owners

Ready to Transform Your Business?

This isn’t just a product. It’s your gateway to a high-demand, recession-resistant, and regulation-backed business with minimal overhead and exceptional ROI.